All About Bayside Laser

Table of ContentsBayside Laser Can Be Fun For AnyoneBayside Laser Things To Know Before You Get ThisIndicators on Bayside Laser You Should KnowFacts About Bayside Laser UncoveredBayside Laser - The FactsGetting The Bayside Laser To Work

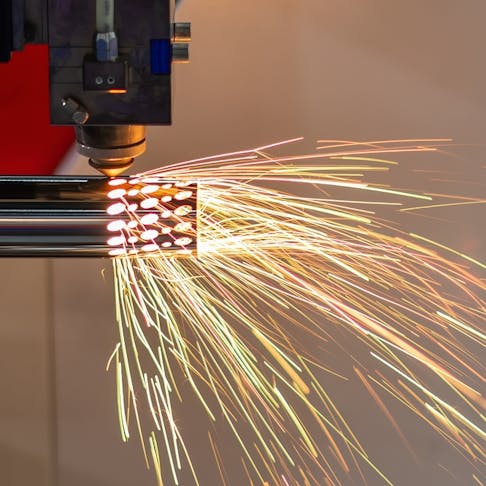

Traveling optic makers need to make use of some technique to consider the altering beam of light size from the near area (near the resonator) cutting to the much area (away from the resonator) cutting. Typical approaches for controlling this include collimation, flexible optics, or the use of a continuous light beam size axis.

The power consumption and also effectiveness of any certain laser will certainly differ depending upon output power and running criteria. This will certainly rely on the kind of laser and just how well the laser is matched to the operate at hand. The quantity of laser cutting power required, called warmth input, for a certain work depends upon the product kind, thickness, process (reactive/inert) utilized, and also preferred reducing rate.

Get This Report on Bayside Laser

The user can conveniently regulate the cut's deepness by changing the laser beam's power and also emphasis (https://www.informationweek.com/profile.asp?piddl_userid=519492). Laser cutting is common in metal, wood, plastics and textiles.

Whether you're seeking a brand-new or upgrading your processes, laser cutting has broad applications, especially in production. That claimed, right here are four advantages of laser cutting: Laser reducing is just one of one of the most sophisticated, accurate and also precise techniques for reducing materials. It can supply a degree of information as well as precision that hand devices can never ever reach.

Bayside Laser for Dummies

The capacity for laser cutting appears virtually infinite as it uses businesses premium basic end results in a fraction of the moment. Laser-cutting innovation is versatile as well as compatible with different materials, varying from wood as well as natural leather to more difficult-to-cut steels. For these harder-to-cut materials, laser cutters develop ideal accuracy cuts that are not available with standard cutting tools.

Laser-cutting makers are as straightforward as a lot of equipment goes. Still, below are four ideas to aid get one of the most out of your procedure: With laser cutting, choosing the ideal material for the work is critical. Relying on the intended application, different products might be better suited than others depending upon variables such as sturdiness and also safety.

The 6-Minute Rule for Bayside Laser

Certainly, laser cutting is a whole lot faster than the standard technique of reducing steel, yet is it faster than other contemporary strategies? Yes, it is. Laser reducing beats thermal cutting methods such as plasma or flame in speed when reducing steel of approximately 10mm thick. That being said, if you want the fastest results you require to collaborate with the most effective steel laser reducing machines such as those utilized by GF Laser that make use of the most up to date Trumpf Laser makers (laser cutting cnc).

For those that require to cut great deals of different forms, laser cutting is certainly the most attractive steel reducing option. With this approach of cutting metal, you do not require to change devices to alter cuts as the exact very same setup will certainly accomplish multiple reducing jobs as long as the density stays the same.

Throughout the laser cutting procedure, the beam of light used does not in fact need to touch the product that is being reduced, resulting in much less threat of damage. This implies that you will certainly not require to incur expensive repairs or postponed completion times as you might with other approaches of reducing steel - laser cutting cnc.

The Single Strategy To Use For Bayside Laser

Laser reducing requires much less power than various other methods, utilizing typically 10k, W of power compared to 50k, W for other reducing procedures. Certainly, the security of your staff members is constantly at the forefront of your mind and laser reducing gives among the most safe ways of cutting metal.

That exact point creates a very high intensity that can cut through the product. Contrasted to typical reducing techniques, laser cutting deals a number of benefits.

Unlike numerous manufacturing machines, laser cutters commonly do not need you to change out different tools for whatever cut you want. Laser cuttings supply severe accuracy contrasted to various other standard cutting methods.

A Biased View of Bayside Laser

Relying on just how a laser cutter is established, you're frequently mosting likely to observe potentially a little burr on a part. Normally, it's not essential to remove the burr, however it relies on the material, its thickness as well as various other factors. Oh yes, this is among the ideal components of using a laser cutter; adaptability.

No work is too complicated for the laser cutter. An extremely slim area of product is easily navigated by the high-powered laser as well as is extremely hardly ever deformed or distorted. Projects are not just limited to sheet metal with a laser cutter. Lasers have the capability to reduce stainless-steel, light weight aluminum, copper, and also brass.